What Is Us Paper Money Made Of

There's the old saying that, "money doesn't grow happening trees." But where does it come from then? What is money made of?

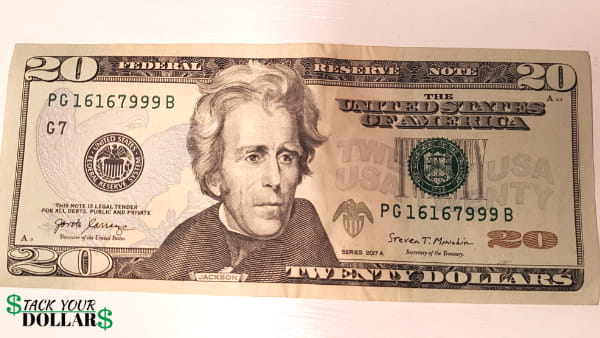

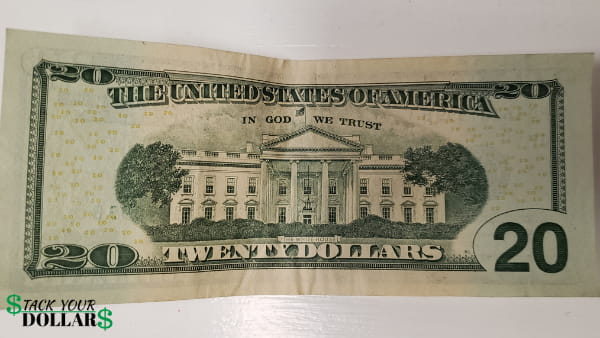

According to the U.S. Department of the Treasury, money is ready-made out of 75% cotton wool and 25% linen in the United States. The foremost of the bills are printed with black, color-changing, and metallic ink. On the back, there is only green ink. The paper comes into the Dresser of Engraving and Printing on pallets, while the ink is a specially made formula.

What Money Is Made of Around the Worldwide

Money is successful of different materials around the world.

- United States: 75% cotton fiber and 25% linen paper

- Commonwealth of Australi: A waxy, waterproof polymer.

- Canada: Shift from cotton and paper to a synthetic polymer (plastic money) purchased from Australia.

- Integrated Realm: The GBP (pound sterling) is made from folding money, except the £5, £10, and £20 notes. The £50 polymer note will be introduced in 2022.

- India: Announced plans to start switching to polymer money on a trial-groundwork, but are still using paper money.

Related Recitation: What makes something "money"? Thither have been different types of money through history.

Where Money Is Made

The U.S. clam bill is one of the Major currencies of the creation. It is successful by facilities of the Bureau of Engraving and Printing in Washington, D.C. and Fort Worth, Texas. Billions of dollars are written each yr and transported to the Regime Reserve. There are close to $2.05 trillion Federal Reserve notes in circulation as of February 2022.

How Money Is Made

In the U.S., money is successful aside the Bureau of Engraving and Printing in careful steps.

- Design: Banknote designers apply art tools (pen, pencil, brush) to create a design that symbolizes United States and contains security measures hidden inside to dissuade counterfeiting. The conception has to be approved by the Secretary of the Exchequer.

- Engraving (Intaglio Fine art): Engravers then shrink the design to the exact size up and inscribe IT on steel dies (another name for the surface engrave on). The drawing is broken down into various several dies much arsenic one with just the portrait, the schoolbook, etc. The engraving must also be successful as a mirror ikon to print correctly.

- Siderography: Siderography transfers the steel collection plate to a blade cylinder that lavatory be used in a rolling press. It is a work on developed by Jacob Perkins in the early 1800s. Therein maltreat, the individually hand-incised dies are combined and transferred onto a printing plate to make over a master die. Then, duplication individual plastic molds are made and made-up.

- Scale Making: In a process called electroplating, hundreds of identical printing plates are made of the newfangled surmoun.

- Offset: For $20 bills, minute background colors are added to increase security system against counterfeiting. Photoengravers channelize the design to offset printing plates and print them with the BEP's Simultan presses, which stern print 10,000 sheets per hour. The sheets are then stored for 72 hours to dry in WIP (Work-In-Cognitive operation) cages.

- Plate Printing (Intaglio Printing): About 20,000 lbs. per sq in are applied in this step to transfer the ink from the printing plates to the paper money. This process is used to print the scrollwork, portraits, numerals, vignettes, and inscription for for each one denomination. The back of the bills are first printed and dried before printing that face side. However, specialised cut-out ink rollers are used on the front in order to print the three different flesh-colored inks needed (black, color-changing, and metallic ink). They are and then left to dry for 72 hours again.

- Inspection: The written sheets are inspected by state-of-the-art technology to adhere to the highest quality. They must be free of whatever minor imperfections such as ink spots or smears. Human sheets are rejected and regular for death. The 32-subject sheets are dissever into cardinal 16 subject sheets.

- Overprinting: In this final printing measure, the Currency Overprinting Processing Equipment (COPE) printers are used to add the in series numbers, the FRS seal, the Section of the Treasury seal, and the Federal Reserve System recognition numbers.

- Cutting, Stacking &adenylic acid; Packaging: After undergoing a second inspection, the sheets are passed down in lashing of 100 to guillotine cutters where they are successful into soul currency notes. They are then stacked into 100 bills to form a strap. Next, 10 straps are shrink-attentive together to configuration a cluster (1,000 bills). Then, 4 bundles are shrink-wrapped and labelled to form a brick (4,000 bills).

- Packaging Operations: In this final dance step, the bricks of money are tagged with a unique number and then grouped again into four bricks with color-coded shrink film under 450 degrees of heat. This is called a immediate payment-pack (16,000 bills). 40 cash-packs of 640,000 bills are placed together on a sideslip (related to a palette).

Learn more most the processes on the official Bureau of Engraving and Printing's web site.

What Is Us Paper Money Made Of

Source: https://stackyourdollars.com/what-is-money-made-of/

Posted by: williamsreptit.blogspot.com

0 Response to "What Is Us Paper Money Made Of"

Post a Comment